If you’re running an automotive reconditioning operation, you already have an established workflow that works – more or less. Making workflows faster and more efficient lets you take advantage of more business opportunities. Software solutions allow you to automate routine tasks, integrate with other tools and systems, and improve communication between teams and departments.

Reconditioning Workflow

Your dealership workflow is the series of steps that lead you to achieve your objective. Workflow efficiency depends on how those steps are organized. To improve workflow efficiency, you need to measure and track its effectiveness, and identify delays and bottlenecks. Your tracking will help you understand where the distribution of tasks is out of balance with the departments or resources assigned to them. Knowing where in the operation a problem exists allows you to make immediate decisions to reorganize or redistribute the work, and effect better outcomes.

Software Solutions Help to Improve Your Reconditioning Workflow

Reconditioning involves multiple steps and multiple contributors to complete each vehicle. If you have more than a few cars in process, the complexity of managing all the moving parts and people can overwhelm traditional manual tracking systems like whiteboards and spreadsheets. Specialized reconditioning management software is designed to manage reconditioning workflows and all the related elements of your reconditioning process.

Automating Tasks – Vital for Improving Dealership Workflow

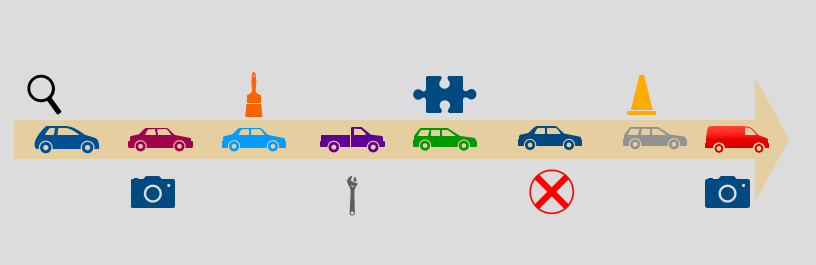

Every vehicle you acquire needs to be processed. Whether it’s a simple inspection and quick wash, or a more involved schedule of repairs, there are pre-defined requirements for how vehicles are handled, based on their incoming condition. As vehicles move through the reconditioning process, they get routed to the appropriate teams or vendors for specific tasks. Managing those tasks, hand-offs, and the work performed is where automation and process enforcement adds value, and facilitates the smooth transition from one reconditioning step to the next. Transport – Inspections – Detailing – Photography – Mechanical Repair – Cosmetic Repair – Parts – Paint – Certification – some or all of these are needed for each vehicle in your used inventory. Coordinating schedules and assignments, and ensuring the shortest cycle-time for each vehicle is a valuable contribution of good workflow software.

Digital Integrations

One of the greatest challenges in auto remarketing is simply the number of different systems and programs used across an organization. You have a DMS or other vehicle inventory management software, another for vehicle location, another for parts, another for timekeeping, for vendor management, etc. Sometimes, these systems can complement each other, but often, they are independent and may not integrate or even communicate with each other. It is crucial that any systems used are able to integrate and communicate with the rest, and that data from these systems is available to all the stakeholders across the organization.

The Sales department needs to know when inventory will be available for sale. Technicians and vendors need to have their work prioritized based on the organization’s needs. The Parts department needs to know what parts are needed as soon as that need is identified. And Management needs to know the status of each vehicle in process, and who has custody. At the same time, there needs to be a real-time mechanism for any stakeholder to communicate and escalate issues, receive timely approvals, and notify others when work progresses. When done right, this reduces idle time, and ensures all stakeholders across the organization have the information they need to contribute.

Complete Visibility

Keeping track of all the work in process becomes exponentially more difficult as the number of vehicles increases. To succeed, you need a system that lets you know the status, location, and person responsible for every car at every stage of reconditioning. Only then will you have command and control of the operation.

Solutions from AMT

ReconMonitor™ and Repair360™ are available from AutoMobile Technologies. ReconMonitor allows you to track and manage workflows, assign tasks and enforce process across all reconditioning activities regardless of location or contributor. Repair360 combines the detailed workflow capabilities of ReconMonitor with full cycle integrated Parts ordering and inventory, Vendor management, Customer scheduling and warranty repairs, and complete team collaboration for a true Reconditioning Management System. Contact us for a free demonstration and to learn how we can help your organization.