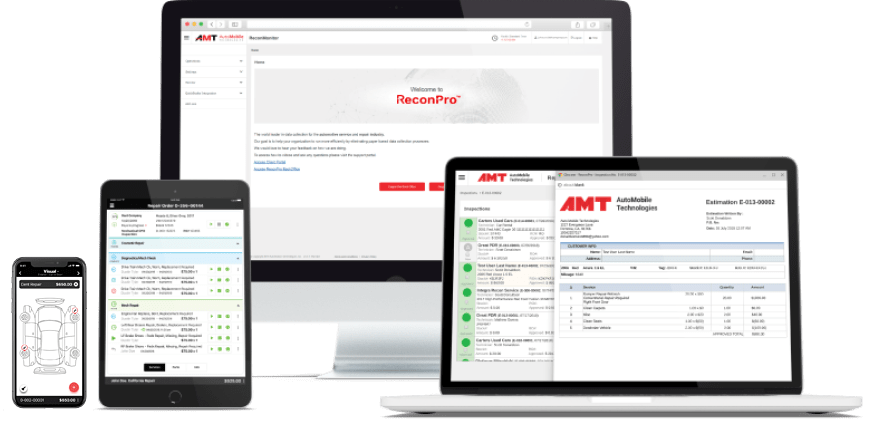

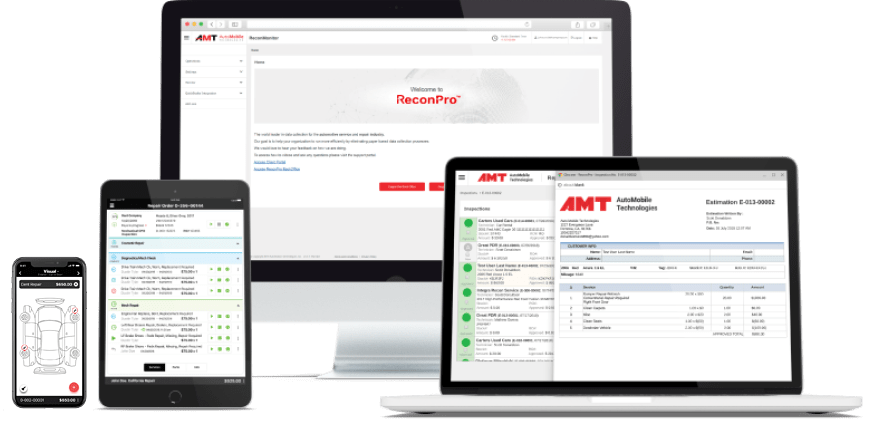

take back control of your car repair business with Powerful Auto Reconditioning Software

Keep track of customers, control auto repair workflows, administrative tasks, and roadblocks in your operation

Includes trim, paint code lookup, vehicle recalls

Fully informed estimates

Know the alternatives

Calculate Flat Rate, % Gross / Net, Tired Commissions, Splits

Create a service menu specific to each account

Set, adjust, and control even the most complex pricing models

Dispatch & Scheduling

On device, via web or quick link

Customized for your business

Share Inspections, Work orders, or Invoices across teams

Your custom business identity and layouts in hard copy

Your custom branding and layouts in emails

Toll Free North America: 1 (888) 600-6898

International: +1 (949) 614-0799

sales@automobiletechnologies.com

support@automobiletechnologies.com

7957 N University Dr., Suite #141

Parkland, FL 33067, USA